What is Duplex I About us I Stockists I Environment

Call 01206 79 2001 for more information

Technical > Lintels and moisture

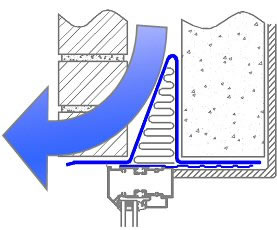

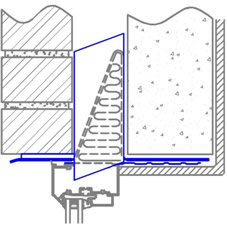

While relevent to all lintels installed in external walls, damp control features are usually restricted to our lintels designed to be installed in cavity walls. The outer leaf of a cavity wall is designed to be damp, and the inner designed to stay dry - relying on the cavity to prevent moisture from reaching the inner leaf. Any items that bridge this cavity should thus be designed to prevent moisture tracking across the cavity to the inner leaf, this includes lintels! Minimum fall across cavity by BS 8215 >>This standard governs the design and installation of damp proof courses (DPCs) in masonry buildings. It states there must be a minimum fall of 150mm across a DPC, to prevent moisture tracking inwards across a cavity. Most of our cavity wall lintels that are over 150mm in section depth have this fall as shown above. This adds an extra barrier to moisture entry even if a seperate DPC is installed above. Each cavity lintel in a catalogue is marked to indicate whether or not a seperate DPC is required due to this 150mm fall requirement. |

COMPLIANCE WITH BS 8215:1991 - DESIGN AND INSTALLATION OF DAMP-PROOF COURSES IN MASONRY CONSTRUCTION

|

|

<< Optional adhesive stop-endsUnless welded stop-ends are ordered, we supply all our cavity wall lintels that meet the minimum fall requirements with flexible adhesive stop-ends, as shown right. There is no need to install a seperate DPC! These stop ends are affixed on site to coincide with mortar joints in the masonry. |

Additional welded stop-ends to make an integral cavity tray >>Where our lintels meet the fall requirement, we can add additional welded stainless steel stop-ends, as shown left. These are specially shaped to prevent moisture spilling from the end of the lintel and tracking across the cavity to the inner. With the addition of these stop-ends, the lintel forms a complete cavity tray and there is no requirement for a seperate DPC. This saves any possibility of the DPC being incorrectly installed or being damaged and thus causing potential damp egress into the construction. Steel stop ends offer the advantage over separate adhesive stop ends of being virtually impossible to compromise, and saving time on site. |

|

| Lintel Materials and damp proof courses Lintels having integral cavity tray features and meeting the surface protection criteria laid out in BS 5977 & BS EN 845-2 may be installed in outer cavity walls without a seperate DPC. Essentially, Hot dip Galvanised and Stainless Steel Lintels are the only lintels that can meet this requirement without onerous additional paint systems being applied. Hence we only offer the option of integral cavity tray features with our stainless steel range of lintels. This means that you can make additional on site savings using stainless steel lintels over pre-galvanised lintels through not having to install a seperate DPC, and your DPC integrity is guarenteed! |

A caution regarding solid external wall Not all external walls are cavity walls, there are plenty of external solid walls! If the external wall is to have a dry inner and damp outer, then a DPC would probably be installed anyway, but there are instances of walls that are likely to be damp on both sides, and still require a lintel, such as courtyard openings etc. In these situations, you must still install a DPC over regular pre-galvanised lintels unless they have additional paint systems applied! The DPC in these cases is only required to protect the Lintel. This is due to the inherently low corrosion resistance of pre galvanised lintels. Many builders would omit to install DPCs in this case, so specifiying stainless steel lintels avoids potential disaster! |